TEMPORARY WORKS #1/04

The next step was to analyse and design a system of Megashore tables that can support the 44T empty

shell beams as well as the infill concrete (additional 45T). On completing the infilling, the partly infilled

beam-column structure should be free standing capable of supporting stage 3 casting loads i.e.

secondary beams and lattice deck.

The FEA analyses showed the 6no RMD tables were required to support the shell beam at this stage.

Grouting the beam column joints earlier was significantly beneficial as it allowed some of the subsequent

wet infill concrete loads to be shared between the falsework and the erected permanent columns.

Though the permanent columns had significant sagging moment capacity they were limited by punching.

The rebar at the column joints were uprated to suit the loadings imposed by the wet concrete. On

completing the partial filling, 5 of the supporting RMD tables were to be removed and reused on different

beam.

The self-supporting beam -column structure at this stage was analysed for supporting the secondary

beams and the lattice floor construction. Since the perm works method did not anticipate any staged

construction the top rebar over columns were all placed in the deck section which wouldn't contribute to

the partly cast shell beam strength under ETW sequence.

The required rebar in the top section within the partly cast shell beam

was determined and then incorporated in the beam enabling the

beam to be self-supporting.

Having developed these innovative solutions, the falsework tables were

then optimised and modularised. enabling RMD tables to be

assembled offsite, transported in and lifted into place speeding up

erection and dismantling of the falsework

The whole site sequence and falsework were modelled in Revit 3D for

clash detection. One potential clash was between the twin wall

propping within the cores and the shell RMD table legs. In

collaboration with site team, we resolved this by partly casting the twin

wall infills enabling the early removal the twin wall props. The clash

was thus avoided.

In conclusion, ETW solution adopted the key strengths/reinforcement

already developed by the permanent works. The shell beams were

enhanced in a few key areas to create an overall efficient and

optimised construction process. In comparison with the permanent

works proposal, the volume of falsework has been reduced by at least

50% with further significant benefit also on construction programme.

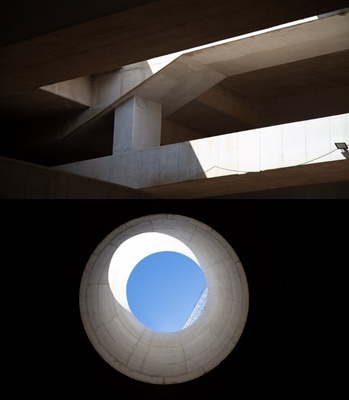

Fig 3: Typical shell beam section